One of the most common questions we get from installers is:

“How much catalyst should I be using?”

And the answer is…it depends on the temperature.

Getting the catalyst ratio right isn’t just a technical detail – it’s the difference between:

- A perfect, workable mix

- Resin flashing off in the mixer

- Or worse… a surface that never fully cures

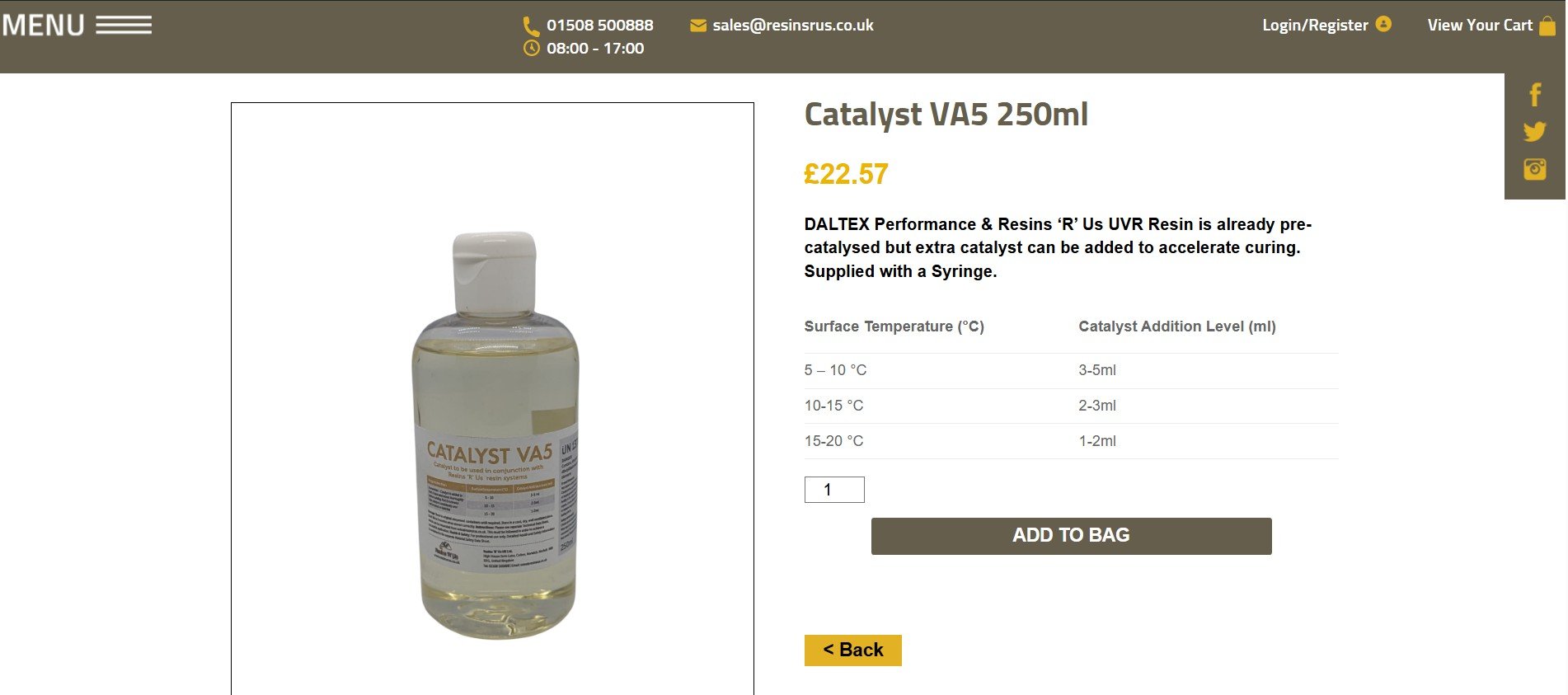

DALTEX Performance & Resins ‘R’ Us UVR Resin is already pre-catalysed, but extra catalyst can be added to accelerate curing. For this reason, a separate catalyst, Catalyst VA5 is available.

What Does Catalyst Actually Do?

Catalyst VA5 controls how fast the resin cures.

- Too much → resin cures too fast, poor workability, weak bonds

- Too little → slow cure, surface remains tacky, failure risk

Temperature directly affects how active the catalyst becomes.

Why Temperature Changes Everything

Resin is temperature-sensitive.

- Cold weather slows the chemical reaction

- Warm weather speeds it up

That’s why the same catalyst ratio behaves very differently in March vs July.

When it comes to resin-bound systems, temperature and moisture really matter.

Install only in dry conditions and ideally between 5°C–26°C. Anything outside that, or incorrect catalyst levels, can lead to curing issues, whitening, patchy finishes, micro foaming or weak bonds.

Responsibility always sits with the contractor/buyer, including making sure:

• Conditions on site are suitable

• Catalyst levels are adjusted to actual ground and air temperatures

• Any third-party fitting teams know exactly what they’re doing

If there’s any doubt, don’t install. Doing it right first time saves time, money and headaches later.

The Golden Rule for Catalyst Use

The warmer it is, the less catalyst you need.

The colder it is, the more catalyst you need.

But there’s a safe working window – and going outside it causes problems.

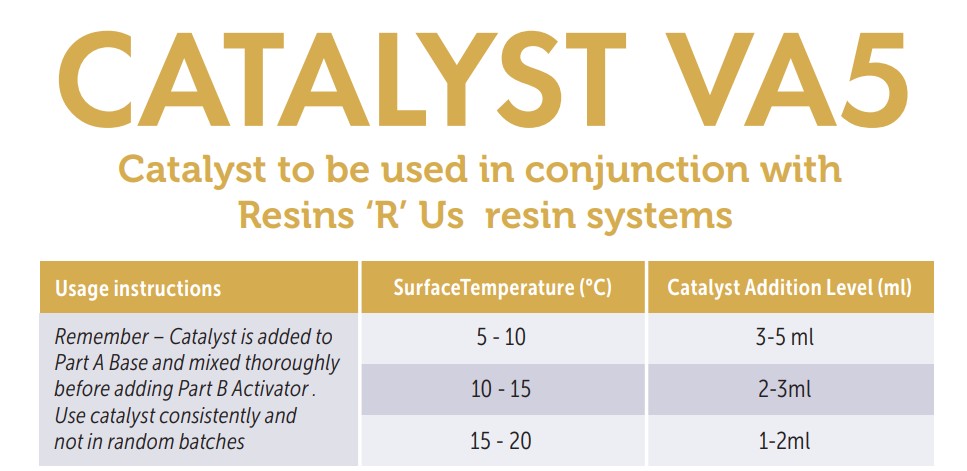

Typical Catalyst Ratios (Guide Only)

| Air / Ground Temp | Catalyst (ml) |

|---|---|

| Below 5°C | ❌ Don’t install |

| 5–10°C | 3-5 |

| 10–15°C | 2–3 |

| 15–20°C | 1–2 |

⚠️ Always follow the data sheet – blends and resin types vary.

Common Installer Mistakes (We See These All the Time)

- Adding extra catalyst to “speed things up”

- Not adjusting for sudden temperature changes

- Ignoring ground temperature (not just air temp)

- Mixing full batches on hot days

- Guessing instead of weighing catalyst accurately

These mistakes lead to cracking, whitening, poor compaction and callbacks.

Pro Installer Tips

✔ Measure Catalyst VA5 by weight, not eye

✔ Reduce batch size in warm weather

✔ Mix in the shade when possible

✔ Check temperature before every mix, not just once

✔ Stop if conditions change – don’t push it

Before You Mix

☐ Check air temp

☐ Check ground temp

☐ Check forecast

☐ Read resin data sheet

Good resin installs are planned, not rushed.

Final Thought

Catalyst control is one of the biggest signs of a professional installer.

Get it right and the job flows.

Get it wrong and the resin controls you.

If you’re ever unsure – ask.

Get the Right Catalyst. Get the Right Result.

Using the correct catalyst – at the correct ratio – is non-negotiable for a successful resin-bound install.

You can:

-

Buy Catalyst VA5 directly from Resins ’R’ Us (matched to our resin systems)

-

Email sales@resinsrus.co.uk or call our friendly service team on 01508 500888 for advice on ratios, temperatures and working conditions

Professional installs start with the right materials – and the right advice.