For the professional resin installer, the final aesthetic layer – the resin-bound mix – is only as good as the groundwork beneath it. At Resins ‘R’ Us, we know that client satisfaction and system longevity are inextricably linked to the integrity of the substrate.

This guide moves past the surface and dives deep into the non-negotiables of ground preparation, ensuring every driveway, path, or patio you install is fully compliant, supremely durable, and a true testament to your craftsmanship.

Mastering Substrate and Groundworks for Permeable Resin-Bound Driveways

Mastering Substrate and Groundworks for Permeable Resin-Bound Driveways

1. The Sub-Grade: Reading the Ground

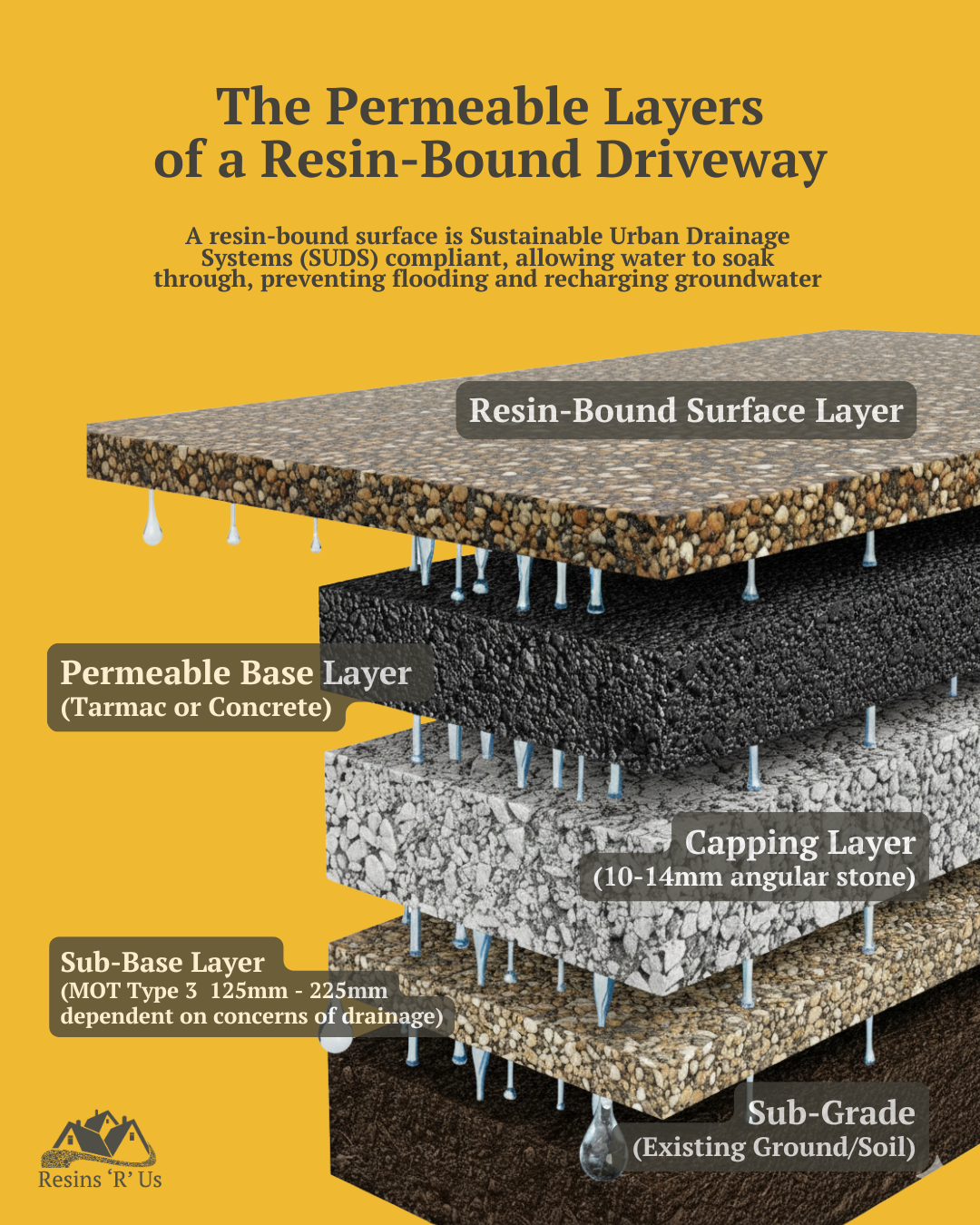

The journey to a perfect permeable surface begins with the Sub-Grade (Existing Ground/Soil). This is the natural, undisturbed soil layer upon which the entire system rests. Ignoring its condition is an invitation for future failures.

Key Installer Action Points, Mastering Substrate and Groundworks for Permeable Resin-Bound Driveways:

- Excavation and Assessment: The first task is to excavate the area to the required depth (accounting for the entire system build-up, typically

to

total depth). Simultaneously, assess the native soil for stability and bearing capacity.

- Contamination and Organics: Strip out all organic matter, roots, and contaminated soil. If the sub-grade is heavy clay or highly saturated, a geotextile membrane should be considered to prevent migration between the soil and the sub-base, offering an added layer of protection against lateral movement.

- Compaction: Ensure the sub-grade is lightly compacted and properly levelled to provide uniform support. Uneven support leads to differential settlement; a major cause of cracking in the upper layers

2. The Sub-Base Layer: The Heavy Lifter

Directly above the sub-grade sits the Sub-Base Layer, often specified as MOT Type 3. This layer is arguably the most critical in terms of load-bearing and, crucially, drainage compliance.

The Role of MOT Type 3: SUDS Compliance

The most significant difference between a standard driveway and a high-specification permeable system is the sub-base material. MOT Type 3 is specifically a “reduced fines” granular material. Unlike standard MOT Type 1, which has fine particles that compact densely and become impermeable, Type 3 is designed to retain gaps and voids when compacted.

This permeability is the core of Sustainable Urban Drainage Systems (SUDS) compliance, allowing surface water to flow directly through to the sub-grade and recharge groundwater, preventing run-off and flooding.

Depth and Drainage Concerns: The to Rule

The diagram specifies a thickness of to , dependent on drainage concerns.

- Minimum 125 mm: This is the standard minimum for residential vehicle traffic, providing adequate load distribution and structural integrity.

- Increased Depth (): If the sub-grade is weak, prone to water logging, or the site is subject to heavier loads (e.g., frequent turning circles, light commercial use), increase the sub-base depth. More material equals greater load-bearing capacity and a larger attenuation zone for water storage before it soaks into the sub-grade.

Key Installer Action Points:

- Layering and Compaction: Lay the Type 3 material in maximum 100 mm

lifts, compacting each layer with a vibrating plate or roller until firm. The compaction should achieve stability, but still allow for permeability.

- Checking Levels: This layer must be laid to precise falls and levels, as any deviations here will be magnified in the subsequent layers

3. The Capping Layer: Precision and Preparation

The layer that directly interfaces with the bound aggregate is the Capping Layer, which should consist of 10 mm−14 mm angular stone.

Why Angular Stone?

The angular nature of this stone is essential for two reasons:

- Interlock: Angular stones mechanically interlock when compacted, creating a stable, load-transferring layer that resists movement.

- Permeability: The defined particle size ensures uniform voids, maintaining the vertical permeability established by the Type 3 sub-base.

The Critical Permeable Base Layer

The diagram identifies this stage as transitioning to the Permeable Base Layer (Tarmac or Concrete). For a high-specification, fully SUDS-compliant system, this layer should be a Permeable Bituminous Macadam (open-graded asphalt) – often referred to simply as “Porous Tarmac.”

Under no circumstances should non-porous concrete or standard dense-graded tarmac be used, as they completely block water flow, nullifying all the permeable groundwork efforts below.

Key Installer Action Points:

- Binder Selection: Use a specialist permeable binder when laying this layer to ensure the voids remain open.

- Curing Time: Allow adequate curing time for the permeable base layer before applying the resin-bound surface. Rushing this stage risks solvent migration or premature curing issues with the resin layer.

- Cleanliness: Before laying the resin, the permeable base must be perfectly clean, dry, and free of fines, dust, or any loose debris. This is the contact surface, and a pristine preparation is vital for strong adhesion.

4. The Surface Layer: Resin-Bound Perfection

Finally, we arrive at the Resin-Bound Surface Layer. By the time you reach this stage, 80% of the job’s structural integrity is already complete, thanks to your meticulous groundworks.

Adhesion and Final Checks

- Primer: While not always mandatory, a specialist polyurethane primer applied to the porous tarmac base can significantly enhance the bond strength, especially in high-stress areas like turning circles or gradients.

- Edge Restraints: Ensure all edge restraints (timber, concrete, or metal) are securely fixed before laying the resin to prevent lateral creep and ensure a crisp finish.

Conclusion: Install With Confidence

The Resins ‘R’ Us product line is designed for longevity, but this can only be guaranteed when installed upon a correctly engineered substrate. By rigorously adhering to the structure outlined in this system, from the stabilised Sub-Grade to the Permeable Base Layer, you deliver a final product that is not just aesthetically pleasing, but structurally superior and environmentally compliant.

Your attention to the sub-surface detail is what truly sets a professional installer apart.

Build it right from the ground up, and the finished driveway will speak for itself.